With EVT in MN/m2

Acceleration sensor

With the Völkel-Compaction-Sensor the vibration behavior of the drum is continuously measured and evaluated by the microprocessor. It is a compaction sensor, vibration and oscillation sensor.

The accuracy of the displayed compaction data is crucial for loss-free data transmission from the sensor to the evaluation electronics. To this end, Völkel has combined the acceleration sensor and the evaluation process on a single circuit board.

Calculated values:

- Soil compaction

- Vibration frequency

- Jump mode

- Vibration amplitude

Detailed information

The Völkel Compaction Sensor for compaction measurement in earthworks and asphalt construction calculates an absolute value EVT for the load-bearing capacity [MN/m2] of the soil on the basis of physical relationships as the roller passes over it. It offers several advantages over other methods:

- Machine-independent: The EVT value takes into account the geometry and forces between the drum and the floor. It delivers comparable load capacity values regardless of the roller type and weight.

- Independent of direction of travel: The equivalent measurement when driving forwards and backwards supports the common way of working without turning maneuvers on construction sites.

- Independent of amplitude: The EVT value is stable even with variable amplitude. This means that CCC measurement runs can also be compacted in a way that conserves resources and materials.

- Robust measured value: The EVT value is just as suitable for soft, cohesive soils as it is for hard rock fills or asphalt. It also works stably in jump mode.

- Extended measured values: In addition to the load capacity, the grade rule, frequency and amplitude are permanently determined.

The compaction energy is determined by calculating the amplitude and the ground contact force. Like the static plate load test, the measurement method uses the compression increase and is based on the evaluation of the force-displacement diagram.

The VÖLKEL Sensors contain both acceleration sensor and evaluation electronics, thus enabling precise measurement. The sensor delivers 10 measured values per second via CANopen; at a speed of 3 km/h, this corresponds to a measuring grid of 10 cm. Thanks to data processing directly in the sensor, several sensors can also be used per machine very easily.

Important roller parameters are taken into account when calculating the EVT value. These include the nominal values of frequency, amplitude and centrifugal force as well as drum width, diameter and line load. Without these parameters, the sensor supports the calculation of the CMV value as fallback level.

ASB:

| Sensor | MEMS 3-axis acceleration sensor |

| Signal transmitter | RGB diagnostic LED in the housing |

| interface | CANopen (maximum baud rate: 1Mbit/s) |

| Connection | Permanently connected cable, 5m, Æ13.4mm, 5-pin M12 plug (pin assignment 1: NC, 2: UB, 3: Ground, 4: CAN High, 5: CAN Low) |

| Power supply | UB = 8..32V, reverse polarity protection |

| Power consumption | 35mA at 12V |

| Degree of protection | IP67, IP69K (DIN EN 60529) |

| Temperature range | -40..85°C (housing temperature) |

| EMC | Directive 2014/30/EU Road vehicles: ISO 10605, ISO 7637-1, ISO 7637-2, ISO 7637-3 Construction machinery: DIN EN ISO 13766-1 Agricultural and forestry machinery: DIN EN ISO 14982 Industrial use: DIN EN 61000-6-2, DIN EN 61000-6-4 |

| Mechanical, climatic resilience | Oscillation: DIN EN 60068-2-6 Shock, continuous shock: DIN EN 60068-2-27 Shocks due to rough handling: DIN EN 60068-2-31 Cold: DIN EN 60068-2-1 Dry heat: DIN EN 60068-2-2 Temperature changes: DIN EN 60068-2-14 Damp heat: DIN EN 60068-2-30 |

| Weight | approx. 0,75kg |

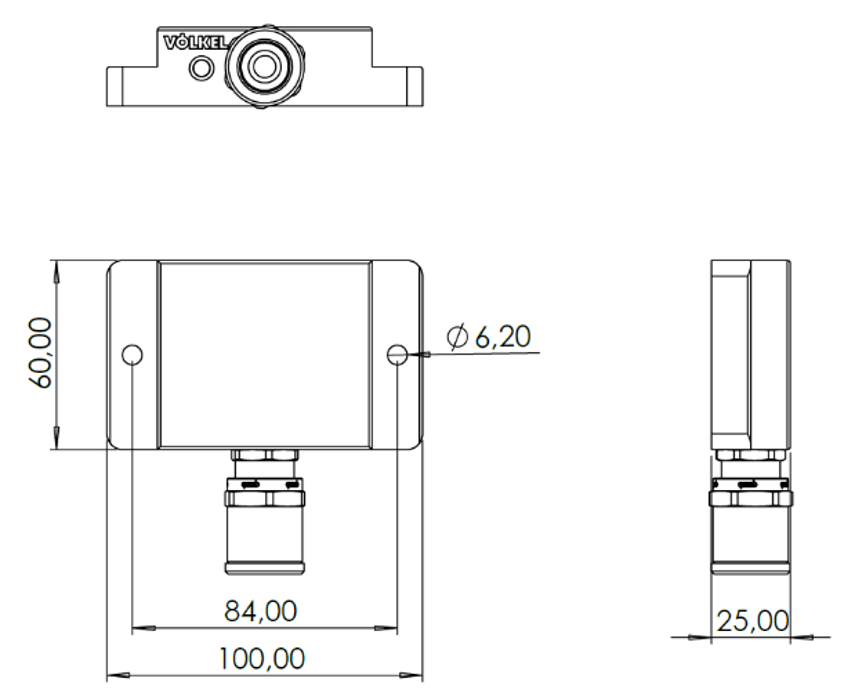

ASB in mm

What can we do for you?

Get in touch

Dirk Jansen Dipl.-Ing. (FH)

Phone +49 2534 9731-0

jansen@voelkel.de

Völkel Mikroelektronik GmbH

Otto-Hahn-Straße 30

48161 Münster