Professional crawler control

HCE-CCP(Crawler Control Professional)

The CCP professional track control system is designed for tracked vehicles that are expected to be more comfortable. These include snow groomers or semi-autonomous trenchers that perform their tasks with GNSS support. The driver should be relieved of operating the driving functions so that he can concentrate on the actual work. The CCP has all the functions of the basic track control system and also has numerous controllers that can be activated as required.

Functions:

- Basic driving functions with various modes

- Driving depending on the diesel speed, control of 2 variable displacement pumps

- limit load control

- Speed, brake pressure, constant pressure regulator

- Overspeed governor, eco operating modes, preparation for steering via GNSS

Detailed information

The CCP professional track control system is designed for tracked vehicles that are expected to be more comfortable. These include snow groomers or semi-autonomous trenchers that perform their tasks with GNSS support. The driver should be relieved of operating the driving functions so that he can concentrate on the actual work. The CCP has all the functions of the basic track control system and also has numerous controllers that can be activated as required.

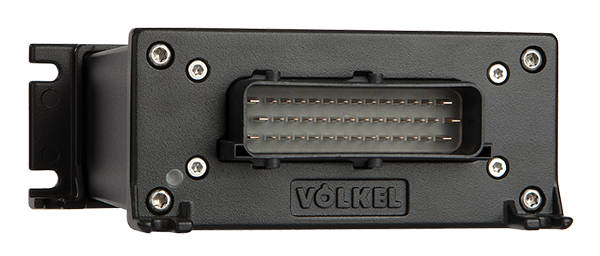

The standard hardware platform for the CCP is the HCE controller. If the CCP is to be integrated into a machine control system, it can easily be ported to another Völkel hardware platform.

The comfort functions in detail

Operation via XY signal

The CCP can be operated like a wheel-driven vehicle: with an accelerator pedal and a steering transmitter or with an XY joystick. The benefit of this is that it can also process the directional specifications of a GNSS receiver. This allows the drive control system to drive a straight line or a partial circle semi-autonomously and independently of disturbance variables using a simple GNSS receiver.

Speed and synchronization control

When speed control is activated using the button, the current driving speed is saved. It serves as a set value for the controller, which acts on the diesel engine, the variable displacement pump and the variable displacement motor. In this way, the speed of both tracks is controlled in a closed loop and kept constant within the physical limits, regardless of the terrain profile. The controller thus ensures that the machine runs in a straight line. If the speed control lever is actuated when the speed controller is active, its value has priority over the set value of the speed controller, provided the set value of the encoder is greater. If the encoder is unloaded, the set value for the travel drive falls back to the stored value. The controller is deactivated by pressing the button again or by pressing the brake.

Constant pressure regulator

High speeds are achieved with a hydrostatic drive by reducing the hydraulic motor displacement. This measure has the effect of increasing the oil pressure required to accelerate the vehicle. If the machine travels uphill, the pressure may exceed a permitted value depending on the travel speed and the tractive force may drop. The constant pressure regulator increases the torque of the hydraulic motor by increasing the displacement. As a result, the pressure is not built up any further, the machine slows down but the tractive force is maintained.

Brake pressure regulator

The brake pressure regulator ensures continuous deceleration during the entire braking process. The braking process is recorded by pressure sensors, and the adjustment times of the hydraulic pump and hydraulic motor are modified depending on the brake pressure and the hydraulic motor’s displacement volume. The deceleration can be extended in the lower speed range to produce a smooth stop. The brake pressure regulator can also help to prevent unwanted shocks and noises during deceleration.

Diesel overspeed protection

The overspeed governor protects the diesel engine from excessive speed during hydrostatic deceleration (overrun operation). If the diesel speed rises to the set speed limit range, the braking power is reduced by adjusting the hydrostat. The overspeed governor has similar characteristics to the brake pressure governor: If no pressure sensors are present, this governor can be used to generate a similarly continuous deceleration. However, it is then dependent on the supporting torque of the diesel engine.

ECO mode

Modern diesel engines require operation with a high load at the operating point so that the exhaust gas aftertreatment functions efficiently. The DCX therefore enables the machine to start up at a lowered diesel speed and drive at the load edge of the diesel engine. If the drive pump is oversized with regard to the required driving performance, the drive train can be operated at the operating point of best efficiency – the machine also reaches its final speed at a reduced diesel speed. The maximum Power is only called up if the ambient conditions require it.

Extended ECO mode

The DCT drive control offers the option of interacting with the working hydraulics control. This means that the diesel engine can be controlled as required and also operated at the load edge, taking into account the working hydraulics. The prioritization of the components in the different operating modes is controlled by the DCT.

AdBlue and soot particle management

If the diesel engine is operated at the optimum operating point, the consumption of AdBlue is lower and the soot particle filter becomes clogged more slowly. If it is not possible to operate the machine in this way due to external circumstances, measures must be taken by the machine control system. Together with a Völkel display, the advanced diesel management of modern engines is supported. Depending on the AdBlue tank level and the condition of the particulate filter, the engine output is limited or regeneration is carried out, for example.

E1 Type approval

The DCE control hardware platform has E1 type approval so that the machine can be approved for use on European roads.

Extended inputs and outputs

Extended inputs and outputs can be read in via the CAN interface.

Control unit: HCE / Application: CCP (Crawler Control Professional)

What can we do for you?

Get in touch

Dirk Jansen Dipl.-Ing. (FH)

Phone: +49 2534 9731-0

jansen@voelkel.de

Völkel Mikroelektronik GmbH

Otto-Hahn-Straße 30

48161 Münster